Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider Sand Aggregate IndustryComprehensive Service Provider

Sand Aggregate IndustryComprehensive Service Provider| model | 1000 x 625 |

| Max feed size | 600 mm |

| CSS Range | 65 – 150 mm |

| Capacity(by hour) | 80 – 210 Mtph |

| Motor power | 110 KW |

| Weight | 16,600 Kg |

*Note: The processing capacity of the 1000 x 625 jaw crusher may vary with different materials and feeding sizes.

Nominal capacity192 – 307 Mtph

Max. feed size750 mm (30")

Motor power

Live ChatNominal capacity

Max. feed size1000 mm

Motor power200 KW

Live Chat

Xinxiang Dingli is a professional mining equipment manufacturer engaged in production of crushing and screening equipment and configuration of the gravel production lines with various capacities.

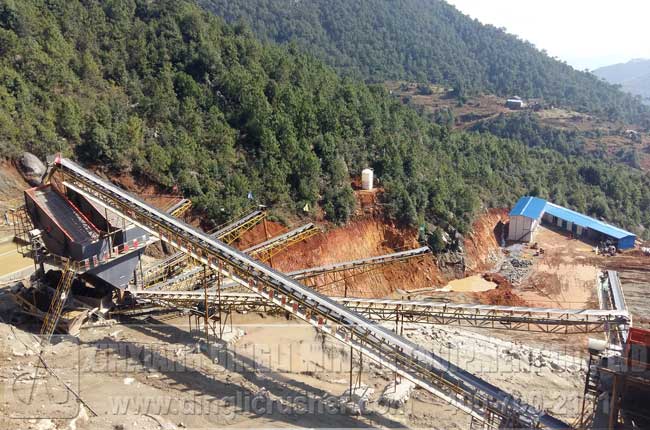

The above pictures show production site of hard rock crusher plant. Unlike traditional crushing plant it adopts only one set of hard rock crusher to complete the crushing process which greatly reduces the equipment investment and increase

Basic configuration :We fully consider the matching adaption of material quality and design process of production line through equipment model selection and reasonable configuration.

Jaw crushers are essential in quarrying operations, where they are used to break down large stones into smaller aggregates, facilitating downstream processing.

Quarrying relies on efficient crushing equipment to transform raw materials into usable products. Jaw crushers play a key role in this process.

Efficiency: High throughput rates and reliable performance make jaw crushers ideal for quarrying operations.

Flexibility: Capable of processing various types of stone, jaw crushers adapt to different quarrying needs.

Durability: Constructed with robust materials, these crushers withstand the rigors of quarrying environments.

Economic Feasibility: Cost-effective to operate, jaw crushers help maintain profitability in quarrying operations.

Integration: Easily integrated into existing production lines, jaw crushers streamline the quarrying process.

Jaw crushers enhance efficiency and productivity in quarrying, contributing to the success of quarrying operations.

We are present worldwide and always here to help.

Get in touch today!